|

|

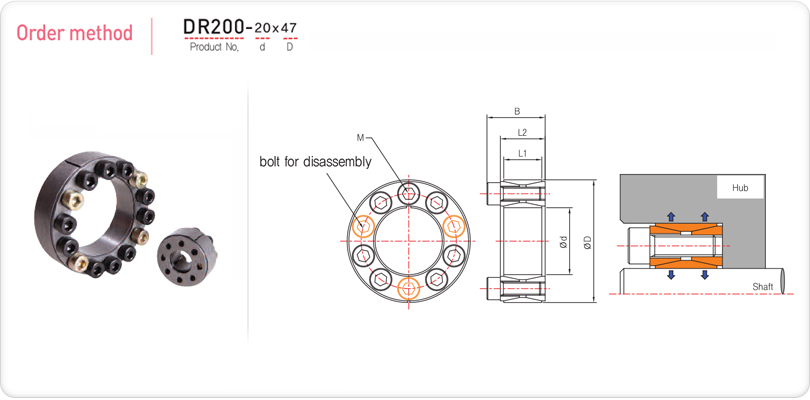

- The product has a potential for high torque transmission.

- It has a hub stationary on the axis when assembled.

- It is easy to mount and disassemble in adjusting its axial direction.

- It can be disassembled by slightly loosening the bolts,

- but special bolts can facilitate the disassembly when there is some rust

- on the surface. |

|

| |

|

- Surface roughness : Rt max16㎛

- Processing tolerance(Max) Shaft : h8, Hub : H8 |

|

| |

|

- it can be widely used – Pulley, Gear, Flywheel, Lever, Cam |

|

|

|

|

| |

|

The process of assembling or disassembling must be done based on how to use the product as described in the document.

Basically, degreasing cannot be allowed because it leads to low transmission torque.

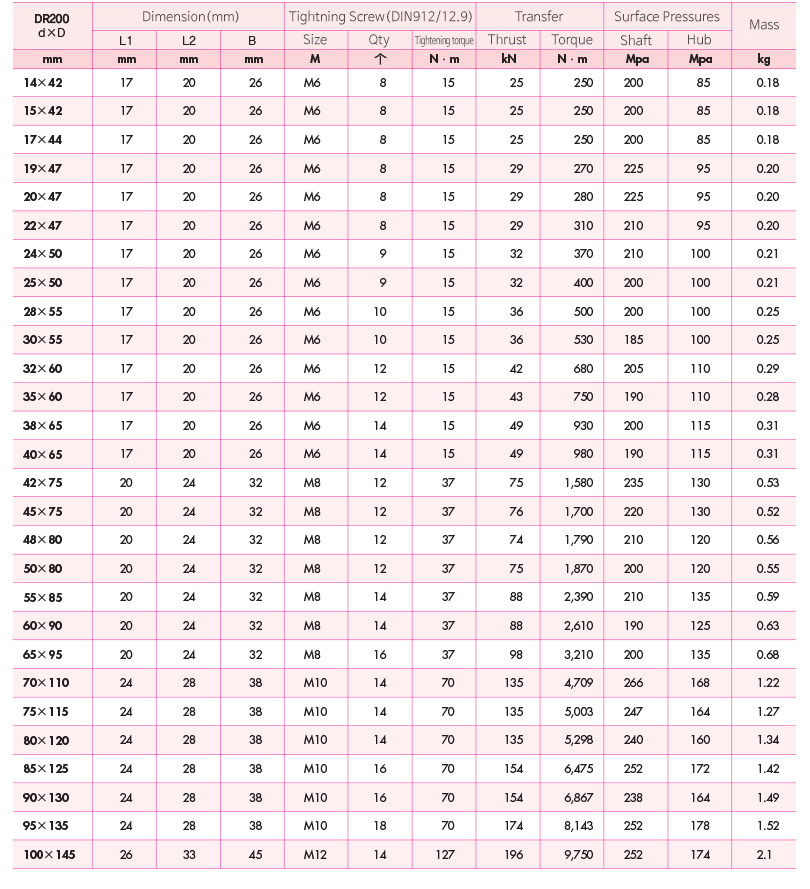

Though DR200 can be used on a multi row, check the strength of the hub and combine torques in compliance with the standard.

Also, transmission torques will not be multiplied in proportion to what the sheets are used. Take care.

If it uses a double row: transmission torque × 1.9

If it uses a triple row: transmission torque × 2.7

Especially, if DR200 is combined with a double row, DR400 type(up to100mm in size) can be recommended. |

|

| |

|

- Adjustments can be made such as interlocking with the hub (for example, h7 on the shaft / H7 on the hub side).

- It is recommended that the hub and the axis be treated with heat.

- Lack of axial strength can result in low transmission torque and the ring being fixed on the shaft.

- Be careful not to have the product deformed and its bolts sagged after being assembled and disassembled.

- The deformation or sagging will make it become obsolete, so it must be replaced with new one. |

|

|

|

| |

|

| |

| |

|

| |

|

| |

|