|

|

- Absence of key grooves on the hub and shaft helps improve more strength

- on its parts.

- This can save energy and space for high torque transmission.

- Much more transmission can be obtained regardless of how large the

- product is.

- Easy adjustment of axial direction can improve operator's work efficiency.

- DR300& DR300C have common types compatible with other products.

- DR300F can be used without any flange designed.

- If DR300(C) is combined on a multi row, DR300EF type (adjustable) can be

- recommended. |

|

| |

|

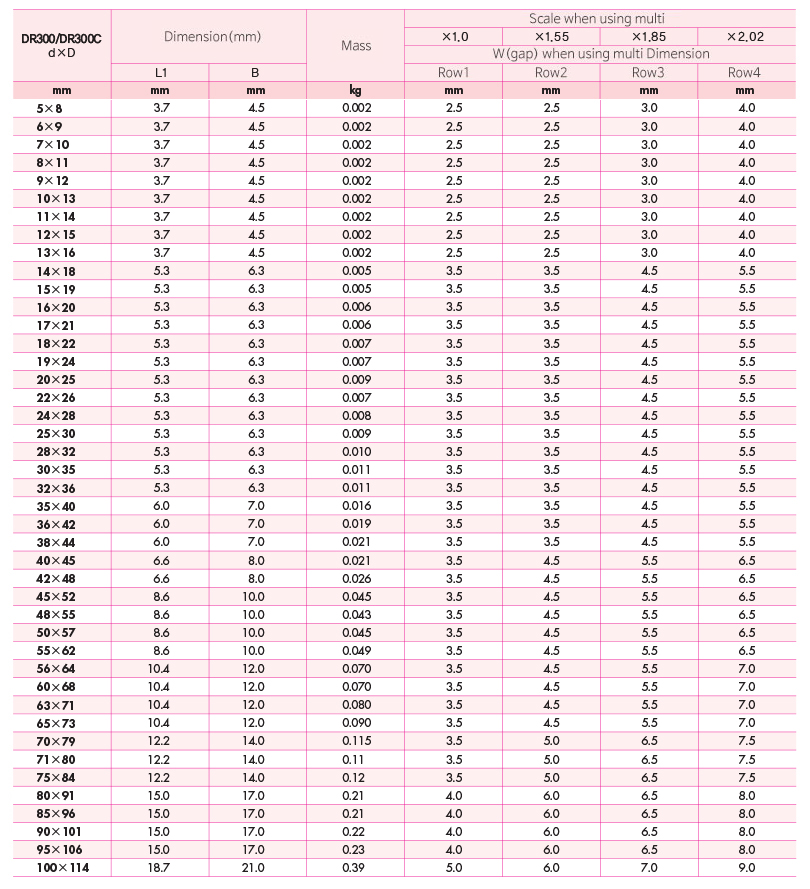

- Surface roughness : Rt max16㎛

- Processing tolerance(Max) :

- d : 40mm Below : Shaft : h6, Hub : H7

- d : 42mm More than : Shaft : h8, Hub : H8 |

|

| |

|

| - Pump, Cam, Sprocket, Pulley, etc. |

|

|

|

|

| |

|

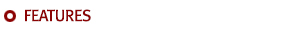

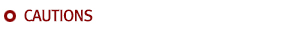

- Adjustments can be made such as interlocking with the hub (for example, h7 on the shaft / H7 on the hub side).

- There are 2 types in terms of axial direction when assembled, whose features must be fully understood.

- If the hub moves with the product assembled, there must be enough space in front or back of the hub.

- If there is no or insufficient space, the product can be difficult to disassemble or it can have low transmission torque.

- It is recommended that the hub and the axis be treated with heat.

- Lack of axial strength can result in low transmission torque and the ring being fixed on the shaft.

- Be sure than larger screw holes must be placed on the flange than the bolts used to assemble the product.

- The bolts can be selected, small in size and many in number, but less than the standard torque.

- DR300F can be applied on the flange as follows.

- Though DR300F can be used on a multi row, check the strength of a hub, clamped torques and bearing pressure more closely.

- Also, transmission torques will not be multiplied in proportion to what the sheets are used. Take care. |

|

|

|

| |

|

| |

<| |

|

| |

|

| |

|